Stage

We are excited to run the Future of Operations & Maintenance (FOM) program again in 2025!

This 100 day signature program gives startups the chance to customize and live-test their solutions to real challenges that DB is facing. What is in it for you?

- Exclusive access to DB experts, data & markets

- EUR 25,000 funding, no equity taken

- Exclusive access to a network of selected coaching and mentoring experts

You will be supported by a dedicated DB mindbox startup manager and will have 24/7 access to our coworking space.

This is a great opportunity to lay the foundation for joint projects and successful long-term collaboration with Deutsche Bahn Group, Europe’s largest mobility and infrastructure provider.

Questions? Check out our FAQs or send an e-mail to the program manager Viviane Elhaus via dbmindbox@deutschebahn.com.

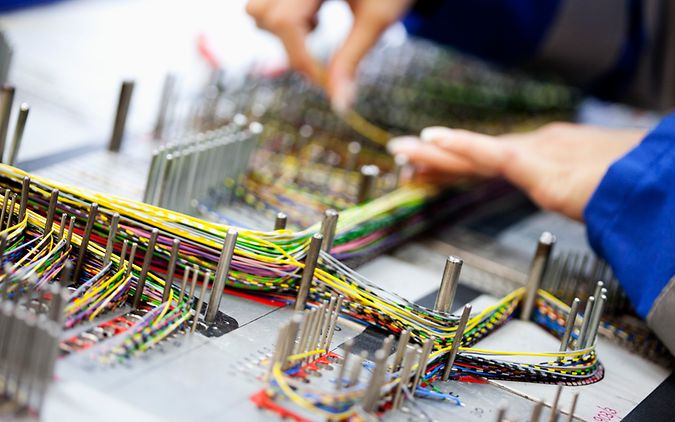

01 - Automating relay assembly processes

We are seeking innovative solutions to automate key production processes at DB's Signalwerk Wuppertal. Relays are critical components of railway infrastructure, particularly in relay interlockings, where they ensure the reliable operation of signals and switches. To keep pace with growing demand, we aim to automate labor-intensive processes involved in the assembly of relay units, including soldering and cable harness binding, both of which are currently performed manually. By streamlining these steps, we can enhance production efficiency while maintaining the high safety and quality standards required for railway operations.

02 - Optimizing maintenance through digitalized circuit diagrams

Together with DB InfraGO (track division) we are looking for new solutions to improve the maintenance of switches, signals and interlocking technology. By digitizing circuit diagrams and integrating advanced tools for technical analysis, we want to reduce downtimes and improve maintenance efficiency.

03 - Innovative solutions for digital train positioning and inventory optimization

Deutsche Bahn's maintenance depots are crucial for the maintenance and repair of the entire train and wagon fleet. With a focus on reliability, safety and efficiency, these factories ensure that rolling stock remains operational. By using new technologies, maintenance facilities aim to overcome challenges such as digital train positioning markers and efficient inventory management.

Within our 100-days proof-of-concept (PoC) will would like to test your innovative technologies that can have a lasting impact on the future of operations. Two key use cases are presented below that highlight the requirements and future visions for improved maintenance and operations.

Timeline

01. Dec. 2024 – Application deadline

Last day to apply for the program (eod).

18. Dec. 2024 – Announcement of candidates

Invitation of selected teams.

29. Jan. 2025 – Selection day

Pitch your solution live on stage to a expert jury and audience in Frankfurt am Main.

25. Feb. 2025 – Start of program

Start of the 100-day Proof-of-Concept (PoC) to develop and test a prototype in cooperation with DB.

05 June 2025 – End of program

End of 100-day Proof-of-Concept and presentation of results.